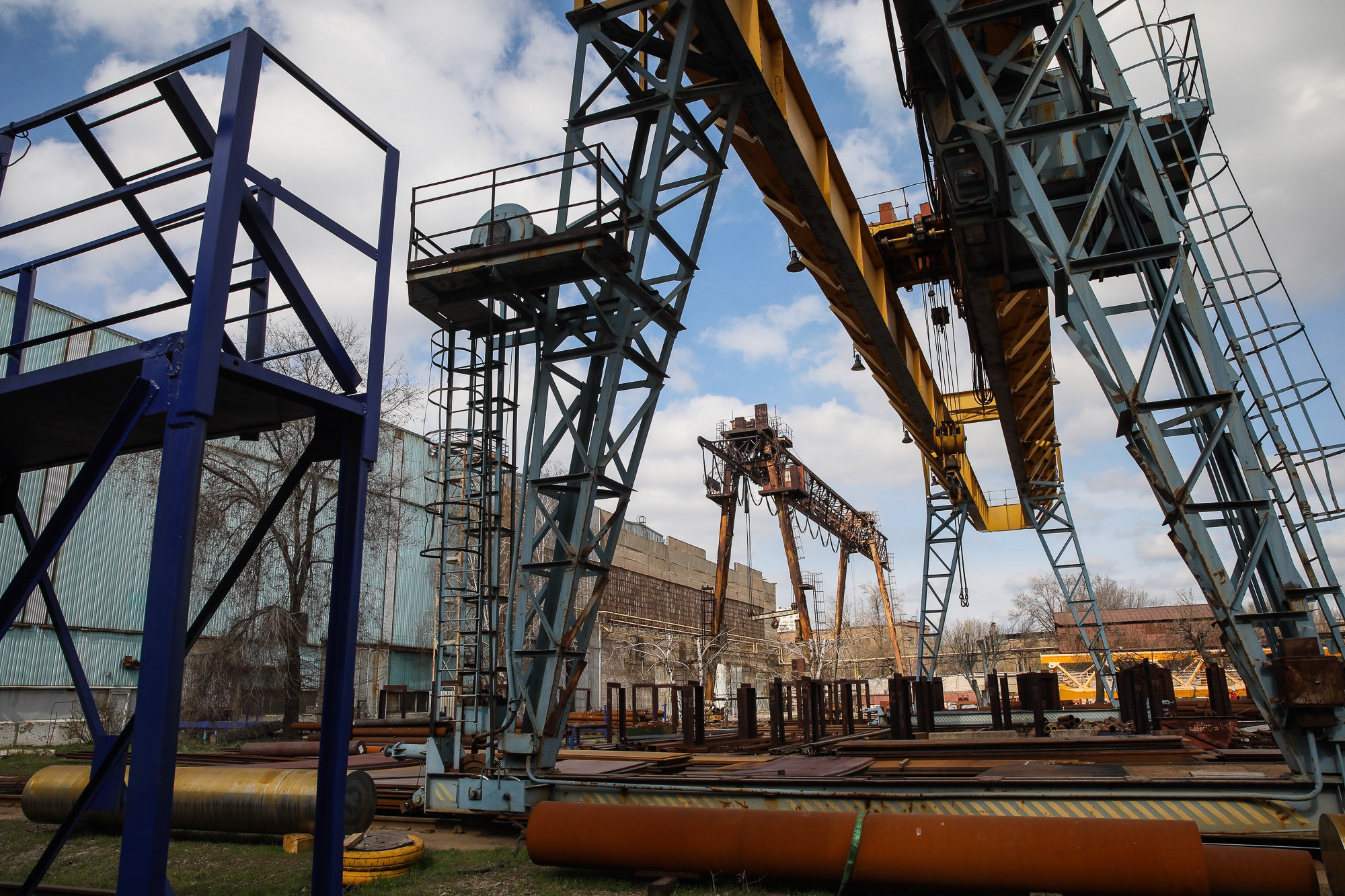

ZAPORIZHIA, Ukraine – Imagine getting a box full of LEGO building blocks to make a toy lifting crane. Now imagine that these building blocks are 30-meters long, made of metal, and can lift 20 tons.

The parts still come packed in a box with an instructions manual to help you assemble them, but this is no toy. It’s a heavy-duty machine used to lift shipping containers in ports, blocks of cement at construction sites, and timber in the logging industry.

Some of these cranes — the premium, expensive ones — are manufactured by Finnish company Konecranes in Zaporizhia. The company’s local plant, Zaporizhkran, buys metal and engines and turns them into top-shelf construction machines.

Locally produced cranes end up at woodworking firms in the United States, at Siemens electronics factories in Germany, or in Finnish ports.

“We mostly export to first-world countries, because our production here is premium and not cheap,” Sergey Plyasov, the CEO of Zaporizhkran and the head of Konecranes in Ukraine, told the Kyiv Post. He said 98 percent of all the cranes go abroad to “big and rich companies.”

A Zaporizhkran employee works on a part of a lifting crane in Zaporizhia on April 9, 2019. (Volodymyr Petrov)

Producing such high-quality machines at this 90-year-old plant became possible only after Konecranes bought Zaporizhkran in 2005. Since then, the Finnish firm has poured a total of 35 million euros into the factory’s development and modernization, according to Plyasov.

“This plant has become the biggest Finnish investment in Ukraine,” he said. “And the Finns are a very rational nation: if they invest, they expect to get a result.”

It took 10 years for the 400-employee plant to turn profitable. But according to Antti Vanhatalo, the Finnish former vice-president of Konecranes and “the father of the acquisition” of Zaporizhkran, it was well worth it.

“We are proud of this plant,” Vanhatalo told the Kyiv Post, showing off the factory’s premises. The industrial building has a high ceiling — a necessity for assembling cranes that reach over 30 meters high.

Each crane costs 5,000–100,000 euros, and the plant makes about 50 of them every year.

“I checked all the plants when we were looking for opportunities in this region, and this one in Zaporizhia was in the best condition,” Vanhatalo said.

Despite that, the buildings’ roofs were leaking and windows were broken, he added.

But Vanhatalo liked this plant not for its physical condition, but because of its talented employees and its location close to local metal plants, which supply Zaporizhkran with raw materials. Today, the plant buys metal from the Mariupol plant that belongs to Metinvest, a company owned by the richest Ukrainian, oligarch Rinat Akhmetov.

Vanhatalo has retired but still regularly visits the plant to offer advice. And the plant’s director, Plyasov, praises his help as well as the corporation’s involvement in local operations.

For Plyasov, the company’s international-ness and its status as part of a major corporation — in 2017, Konecranes boasted a revenue of $3.5 billion — is palpable in the daily work of Zaporizhkran. Unlike in virtually all other enterprises in Zaporizhia, all corporate communication at the factory is in English and there are always foreigners visiting. Even the line managers in the factory speak English.

“The Finns care and always help. They bring the European mentality and style of work to our local plant,” Plyasov said. Even though Konecranes has owned the plant for 14 years, every week there’s someone from the global offices dropping by to help them, he added.

“And these are not auditors who come to inspect their property. These are people who come to share technology, business approaches,” he said. “They believe that only a strong global team can succeed.”

Plyasov doesn’t envy those companies that are exclusively Ukrainian and “stew in their own juices,” not having access to world’s latest business developments.

Close to frontline

Zaporizhkran is heavily dependent on export. But in 2014, when Russia launched its war against Ukraine, the factory struggled to get orders. Many customers even cancelled orders, and the factory’s employees worked just four days a week. There was little to do.

Then, in 2015, the Russian-backed forces attacked Mariupol, a port city 200 kilometers south of Zaporizhia. “There were talks of shutting down the plant at the time,” Plyasov, a native of Mariupol, said. “But we survived.”

The plant started committing only to short-term projects that looked less scary to the clients: It began selling just parts of cranes. As a result, 70 percent of today’s production capacity goes on making and selling parts. For example, Zaporizhkran is making chassis for 86 cranes that the U. S. Port of Virginia ordered from Konecranes.

Today, the war looks less scary to customers, and so more of them started to place orders, said Plyasov,

Meanwhile, being a part of such an established international organization gives only benefits, according to Plyasov. Although “the local market is dead,” Zaporizhkran always has orders lined up two to three years in advance.

He says the plant has everything necessary to ramp up production from the current 40–50 cranes a year.

It just needs more people, but finding them is hardly straightforward.

In general, all the heavy industry suffers from the lack of engineers, because most students today study creative professions like designers, journalists, and lawyers.

On top of that, skilled tech specialists leave Ukraine for the European Union, where salaries are higher.

The average salary at Zaporizhkran is around 350 euros, while Polish enterprises pay 800–1,000 euros.

“This is a difficult situation. But I don’t remember when the situation was simple in Ukraine,” Plyasov said. “The important thing is that we work stably and manufacture good cranes no matter what.”